The Future of Thermal Imaging in Industry and Safety

Unlocking the Power of Thermal Imaging: How Thermal Imagers Transform Industries and Enhance Safety

In a world where safety and efficiency reign supreme, thermal imaging technology is revolutionizing industries like never before. From construction sites to healthcare facilities, thermal imagers are unlocking a new dimension of insight, enabling professionals to detect issues invisible to the naked eye. These sophisticated tools transform not only how we monitor structural integrity and energy efficiency but also how we prioritize safety in our daily operations. Imagine being able to anticipate equipment failures before they happen, diagnose medical conditions with precision, or identify hazards in hazardous environments—all through the power of thermal imaging. As we delve into the transformative impact of this technology, you'll discover how it enhances operational efficiency, bolsters safety protocols, and opens doors to innovative solutions across various sectors. Join us on this journey to explore the profound benefits of thermal imagers and how they are reshaping the way we approach safety and operational excellence.

How Thermal Imaging Works

Thermal imaging, also known as infrared thermography, is a technology that captures and visualizes the infrared radiation emitted by objects. Every object with a temperature above absolute zero emits infrared radiation, which is invisible to the human eye but can be detected by thermal imagers. These devices convert the infrared radiation into a visible image that represents the temperature distribution on the surface of the object. The resulting thermal images, or thermograms, use color variations to indicate different temperature levels, providing a visual representation of heat patterns.

The core component of a thermal imager is the infrared sensor, often referred to as a microbolometer or a focal plane array (FPA). This sensor detects the infrared radiation and converts it into electrical signals. These signals are then processed by the imager’s onboard computer to create a thermal image. Advanced thermal imagers may include additional features such as image enhancement, calibration tools, and the ability to overlay thermal images onto visible-light images for more detailed analysis.

One of the key advantages of thermal imaging is its non-contact and non-invasive nature. Unlike traditional temperature measurement methods that require physical contact or insertion of probes, thermal imagers can measure temperature from a distance. This capability makes them ideal for inspecting high-voltage electrical systems, monitoring large areas, and accessing hard-to-reach places. Thermal imaging is also effective in complete darkness and through smoke or fog, providing clear and accurate images regardless of environmental conditions.

Key Industries Utilizing Thermal Imaging

Thermal imaging technology has found applications across a wide range of industries, each benefiting from its unique capabilities. In the electrical and mechanical sectors, thermal imagers are indispensable tools for preventive maintenance and condition monitoring. By detecting abnormal heat patterns, technicians can identify potential issues such as overheating motors, loose electrical connections, and failing bearings before they lead to costly failures or safety hazards.

In the construction and building inspection industry, thermal imaging plays a crucial role in assessing the thermal performance of buildings. It helps identify areas of heat loss, poor insulation, and moisture intrusion, enabling builders and inspectors to address energy efficiency and structural integrity concerns. By visualizing temperature variations, thermal imagers can reveal hidden problems such as water leaks, missing insulation, and thermal bridging, which are otherwise difficult to detect.

The healthcare sector has also embraced thermal imaging for its diagnostic and monitoring capabilities. Medical professionals use thermal imagers to detect abnormal temperature patterns associated with conditions such as inflammation, infection, and circulatory disorders. In breast cancer screening, thermal imaging serves as a supplementary tool to identify irregular heat patterns that may indicate the presence of tumors. Additionally, thermal imaging is used in veterinary medicine to monitor the health of animals and detect injuries or infections.

The Role of Thermal Imaging in Safety and Risk Management

Safety and risk management are paramount in many industries, and thermal imaging is a powerful tool in enhancing these protocols. In the realm of firefighting and emergency response, thermal imagers provide critical situational awareness. Firefighters use thermal imagers to navigate through smoke-filled environments, locate hotspots, and identify trapped individuals. The ability to see through smoke and darkness significantly improves the efficiency and safety of rescue operations.

In industrial settings, thermal imaging is integral to maintaining a safe working environment. It helps identify potential hazards such as overheating equipment, electrical faults, and gas leaks. By detecting these issues early, maintenance teams can take preventive measures to mitigate risks and prevent accidents. Thermal imagers are also used in predictive maintenance programs to monitor the condition of machinery and infrastructure, reducing the likelihood of unexpected failures.

Thermal imaging is also valuable in security and surveillance applications. Security personnel use thermal imagers to monitor perimeters, detect intrusions, and conduct search and rescue operations. Unlike traditional cameras, thermal imagers are effective in low-light and adverse weather conditions, providing reliable surveillance capabilities around the clock. This enhances the overall security posture and helps protect assets and personnel from potential threats.

Benefits of Using Thermal Imagers

The benefits of using thermal imagers are manifold, extending far beyond simple temperature measurement. One of the most significant advantages is the ability to detect problems early, allowing for timely intervention and prevention of costly downtime or damage. In industrial settings, this translates to increased operational efficiency and reduced maintenance costs. By identifying issues before they escalate, thermal imaging helps extend the lifespan of equipment and infrastructure.

Thermal imaging also enhances energy efficiency by identifying areas of heat loss and poor insulation. In the context of building inspections, this leads to more informed decisions regarding energy-saving improvements. Homeowners, builders, and facility managers can use thermal imaging to optimize heating and cooling systems, reduce energy consumption, and lower utility bills. The environmental benefits of improved energy efficiency contribute to sustainability efforts and the reduction of carbon footprints.

Another key benefit is the non-intrusive nature of thermal imaging. Without the need for physical contact, thermal imagers can safely inspect live electrical systems, high-temperature machinery, and hazardous environments. This reduces the risk of injury to personnel and minimizes disruptions to ongoing operations. Furthermore, thermal imaging is a versatile tool that can be adapted to a wide range of applications, from industrial maintenance to medical diagnostics, making it a valuable asset across multiple sectors.

Common Applications of Thermal Imaging

The applications of thermal imaging are diverse and continually expanding as technology advances. In the realm of electrical and mechanical maintenance, thermal imagers are used to inspect electrical panels, circuit breakers, and transformers. By detecting hotspots and uneven temperature distributions, technicians can identify overloaded circuits, loose connections, and equipment at risk of failure. This proactive approach to maintenance minimizes downtime and enhances the reliability of electrical systems.

In the construction industry, thermal imaging is used to assess building envelopes for energy efficiency. It helps identify thermal bridges, air leaks, and missing insulation, which contribute to heat loss and increased energy consumption. Builders and inspectors use thermal images to visualize and document areas that require attention, ensuring that buildings meet energy efficiency standards and provide optimal comfort for occupants.

Thermal imaging is also widely used in the field of medicine. Medical professionals utilize thermal imagers to detect abnormal temperature patterns associated with various health conditions. For example, thermal imaging can aid in the early detection of breast cancer, monitor the progression of vascular diseases, and assess the extent of inflammation or infection. In veterinary medicine, thermal imaging is used to diagnose and monitor the health of animals, providing valuable insights without causing stress or discomfort.

Choosing the Right Thermal Imager for Your Needs

Selecting the right thermal imager depends on several factors, including the intended application, required resolution, and budget. One of the key considerations is the thermal resolution, which determines the level of detail in the thermal images. Higher resolution imagers provide clearer and more detailed images, making them ideal for applications that require precise temperature measurements and detailed analysis.

Another important factor is the temperature range and sensitivity of the thermal imager. Different applications require different temperature measurement capabilities. For instance, industrial applications may require imagers with a wide temperature range to monitor high-temperature equipment, while building inspections may require imagers with high sensitivity to detect small temperature differences. Understanding the specific requirements of your application will help you choose an imager with the appropriate specifications.

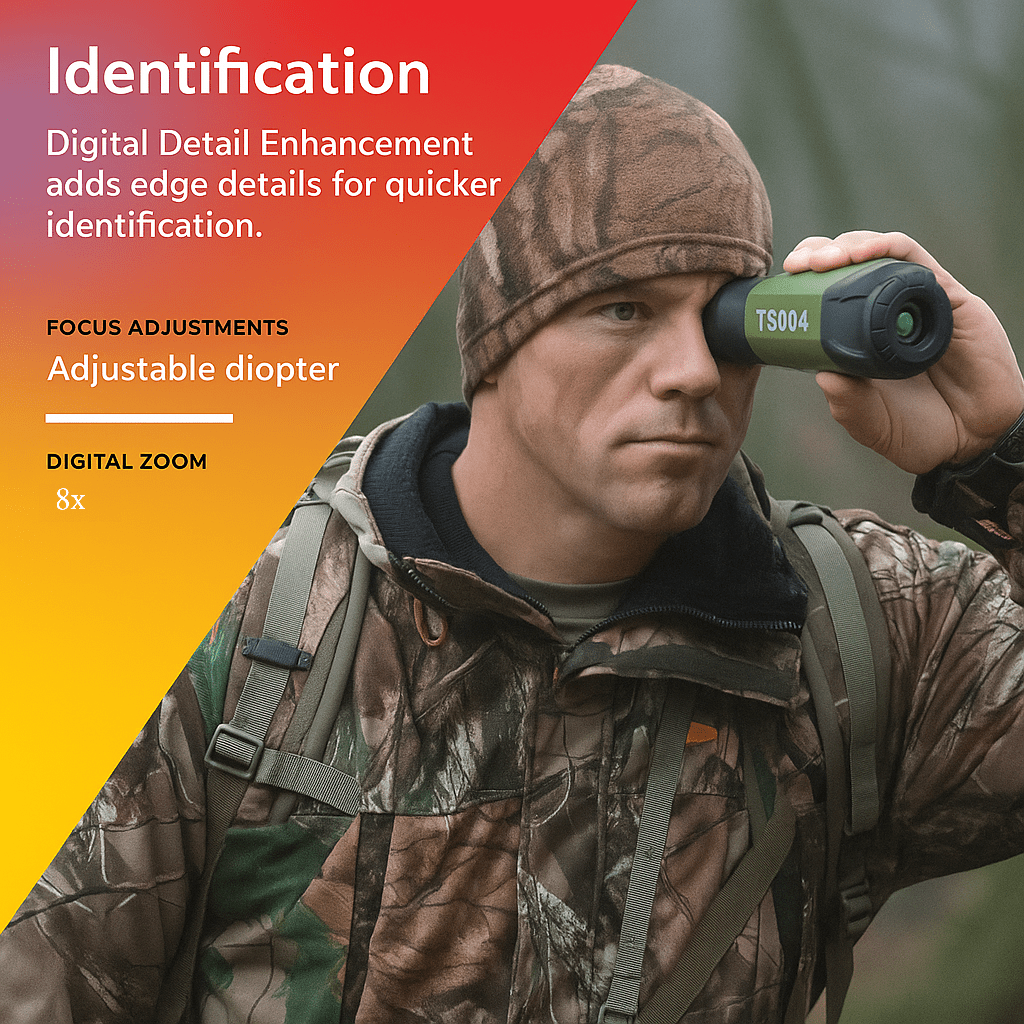

Additional features such as image enhancement, data storage, and connectivity options can also influence your decision. Some thermal imagers offer advanced features like real-time video streaming, Wi-Fi connectivity, and integration with mobile devices. These features can enhance the functionality and convenience of the imager, making it easier to capture, analyze, and share thermal images. Ultimately, the right thermal imager for your needs will balance performance, features, and cost to provide the best value for your specific application.

Future Trends in Thermal Imaging Technology

The future of thermal imaging technology is bright, with continuous advancements driving new applications and capabilities. One of the emerging trends is the integration of artificial intelligence (AI) and machine learning with thermal imaging. AI algorithms can analyze thermal images in real-time, identifying patterns and anomalies that may indicate potential issues. This intelligent analysis enhances the accuracy and efficiency of inspections, enabling faster and more informed decision-making.

Another trend is the miniaturization and portability of thermal imagers. As technology advances, thermal imagers are becoming smaller, lighter, and more portable, making them more accessible and convenient for field use. Handheld thermal imagers and smartphone attachments are becoming increasingly popular, allowing professionals to carry powerful thermal imaging tools in their pockets. This portability expands the range of applications and makes thermal imaging more versatile and user-friendly.

The integration of thermal imaging with other technologies such as drones and augmented reality (AR) is also on the rise. Drones equipped with thermal cameras can conduct aerial inspections of large areas, such as solar farms, pipelines, and power lines, providing valuable thermal data from a unique perspective. AR applications can overlay thermal images onto real-world views, enhancing situational awareness and providing intuitive visualizations for complex inspections. These integrations are set to revolutionize the way thermal imaging is used across various industries.

Case Studies: Successful Implementation of Thermal Imaging

Thermal imaging has been successfully implemented in numerous case studies, showcasing its transformative impact across different industries. In the electrical industry, a power utility company used thermal imagers to conduct routine inspections of their transformers and switchgear. By detecting hotspots and abnormal temperature patterns, they were able to identify potential failures before they occurred, reducing downtime and maintenance costs. The proactive approach also enhanced the reliability of their electrical distribution network, ensuring consistent power supply to their customers.

In the construction industry, a building inspection company used thermal imaging to assess the energy efficiency of a commercial building. The thermal images revealed significant heat loss areas due to poor insulation and air leaks. Based on the findings, the building owner implemented targeted improvements, including adding insulation and sealing gaps. The result was a significant reduction in energy consumption and improved thermal comfort for the occupants. The use of thermal imaging provided clear evidence of problem areas and guided effective remedial actions.

In the healthcare sector, a hospital implemented thermal imaging for breast cancer screening as a supplementary tool to mammography. Thermal imaging helped identify abnormal heat patterns associated with tumors, providing additional diagnostic information. The non-invasive nature of thermal imaging made it a comfortable option for patients, and its use as a complementary tool enhanced the overall accuracy of breast cancer detection. The hospital reported early detection of several cases, leading to timely treatment and improved patient outcomes.

Conclusion: The Future of Thermal Imaging in Industry and Safety

The transformative power of thermal imaging is evident across various industries, enhancing safety, efficiency, and operational excellence. As technology continues to evolve, thermal imagers are becoming more advanced, portable, and integrated with other innovative solutions. The ability to visualize temperature patterns and detect issues invisible to the naked eye provides invaluable insights that drive informed decision-making and proactive maintenance.

Looking ahead, the integration of AI, miniaturization of devices, and the combination with other technologies such as drones and AR will further expand the capabilities and applications of thermal imaging. These advancements will open new frontiers and provide even greater benefits across sectors ranging from industrial maintenance and construction to healthcare and security.

As we continue to unlock the full potential of thermal imaging, it is clear that this technology will play an increasingly critical role in shaping the future of industry and safety. By embracing thermal imaging, professionals can enhance their ability to detect, diagnose, and prevent issues, ultimately contributing to safer, more efficient, and sustainable operations. The journey of thermal imaging is far from over, and its impact will continue to grow as we explore new possibilities and applications for this powerful technology.